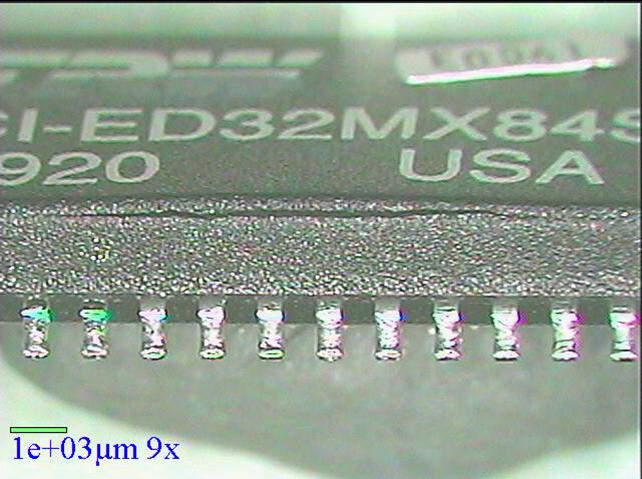

A semiconductor device is only as good as its reliability: the probability that it will perform its function under specified conditions for a set time. Today's ICs possess shorter lifetimes and reduced reliability margins, and rapid developments have led to the use of materials that are not well characterized. While reliability levels are at an all-time high level in the industry, rapid changes may lead to unintentional failures and the inability to predict when devices might fail.

Semiconductor reliability is at a crossroads. In the past, reliability meant discovering, characterizing and modeling failure mechanisms and determining their impact on the reliability of the circuit. Today, reliability can involve tradeoffs between performance and reliability, assessing the impact of new materials, dealing with limited margins, etc. Analysis and experimentation is now performed at the wafer level instead of the packaging level. This requires knowledge of subjects like: design of experiments, testing, technology, processing, materials science, chemistry, and customer expectations. While reliability levels are at an all-time high level in the industry, rapid changes may quickly cause reliability to deteriorate. Your company needs competent engineers and scientists to help solve these problems. This Reliability Online Course is an online version of the 4-day Semiconductor Reliability course that offers detailed instruction on a variety of subjects pertaining to semiconductor reliability. This course is designed for every manager, engineer, and technician concerned with reliability in the semiconductor field, using semiconductor components, or supplying tools to the industry.