Failure Analysis requires semiconductor design and processing knowledge, logical thinking, and detective skills. In many respects, the job of failure analyst is much like the job of a detective. The failure analyst must search for clues and evidence as to what might have caused the circuit to fail the way it did. Each and every clue that the analyst uncovers (through testing or examination) may potentially be important. This requires that the analyst be organized and develop a story that makes sense. In other words, the failure mechanism found must correlate to the observed failure mode.

There are also several guiding practical principles when performing failure analysis. The first and most important principle is to understand what detail of analysis is required by your customer. This is important for two reasons. One reason is that we do not want to perform extra work if it is not necessary. Performing an in-depth, detailed analysis may not be necessary if all the customer wants to know is whether or not he or she damaged the device. The second reason is that we do want to take extra care and precaution for a critical failure. For example, if the device we are analyzing is suspected to have caused the failure of a satellite launch, we will want to take extra care and perform the analysis in a great amount of detail.

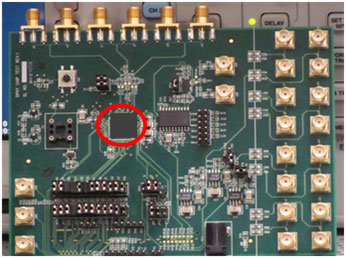

Being able to understand what techniques to perform in what order is the hallmark of a mature product analyst. Determining what techniques to perform and what tests to run require both knowledge of the techniques and philosophy behind failure analysis, as well as an understanding of the product to be analyzed. To learn more about this topic, examine the materials in this workspace.