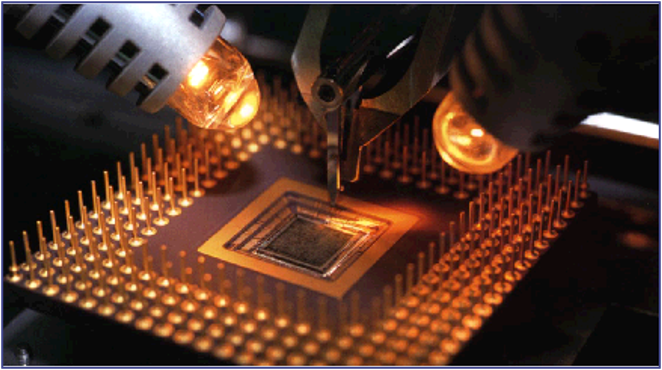

Semiconductor Packaging is increasingly important to the success of almost all electronic systems. One traditional packaging process that is still used extensively today is Wire Bonding. Although Wire Bonding is an established technology, there are still areas of development, such as fine pitch wire bonding, wire loop control, wire bonding with new metals, and new materials on the die that require re-thinking the process parameters associated with wire bonding. Wire Bonding is an 8-hour online course that offers detailed instruction on the technologies used to create the connections between the semiconductor die and the leadframe or substrate. This includes materials for wire bonding, equipment for wire bonding, key process parameters, and applications for wire bonding. We place special emphasis on current issues related to wire bonding on current generation products, as well as reliability issues. This course is a must for every manager, engineer and technician working in the semiconductor industry, using semiconductor components or supplying tools to the industry.

Participants learn basic but powerful aspects about the semiconductor packaging. This skill-building series is divided into four segments:

1. Wire Bonding Overview. Participants study the wire bonding processes that are associated with package manufacturing to learn about the issues facing wire bonding technology. They learn why cost and high-volume manufacturing have become critical to semiconductor packaging for today’s designs.

2. Current Issues. Participants learn the issues surrounding the introduction of low-k materials on the die and their impact on packaging, the introduction of copper wire and its impact on wire bonding, and the impact of parasitics when implementing a wire bonding configuration.

3. Reliability. Participants learn the fundamentals of reliability for wire bonding. We discuss how contamination, humidity, temperature cycling, and thermal stresses can affect the reliability of the wire bond.

4. Examples. Participants will see a number of examples of wire bonds, and wire bonds used in a variety of different applications.

1. The course will provide participants with an in-depth understanding of wire bonding technology and its technical issues.

2. Participants will understand the issues behind wire bonding technology and why we are facing certain predicaments.

3. The course will identify the key issues related to the use of wire bonding in the semiconductor industry. This includes the need for bonding methods that can minimize potential damage, due the increasing fragility of the die because of low-k dielectrics.

4. Participants will understand how wire bonding techniques, cleaning methods, and packaging materials relate to reliability.

5. Participants will be able to make decisions about how to construct and evaluate new wire bonding techniques.

6. The participant will also be introduced to the types of metals being used for wire bonding, including aluminum, gold, copper, palladium-coated copper (PCC), and silver.