Yield Analysis is an increasingly difficult and complex process. Today, engineers are required to locate defects on complex integrated circuits. In many ways, this is akin to locating a needle in a haystack, where the needles get smaller and the haystack gets bigger every year. This is made even more complex by the tremendous amount of data produced by fab tools and test systems. Engineers are required to understand a variety of disciplines in order to effectively perform yield analysis. This requires knowledge of subjects like: design, testing, technology, processing, materials science, data mining, and statistics. Low yields on a high-volume manufacturing line can cost a company millions of dollars a day. Your industry needs competent analysts to help solve these problems. Fundamentals of Yield is an online course that offers detailed instruction on a variety of effective tools, as well as the overall process flow for identifying, locating and characterizing the defects responsible for the low yields. This course is designed for every manager, engineer, and technician working in the semiconductor field, using semiconductor components or supplying tools to the industry.

By focusing on a Do It Right the First-Time approach to the analysis, participants will learn the appropriate methodology to successfully locate defects, characterize them, and determine the root cause of failure.

Participants learn to develop the skills to determine what tools and techniques should be applied, and when they should be applied. This skill-building series is divided into four segments:

- Yield Concepts. Participants learn about the various ways that yield is expressed within a production factory. They learn about yield models and how to estimate yield based on defect densities, area, and other factors.

- Test Structures for Evaluating Yield. Participants learn about various test structures and parametric test techniques to evaluate the yield, and to correct test structure yield to product yield.

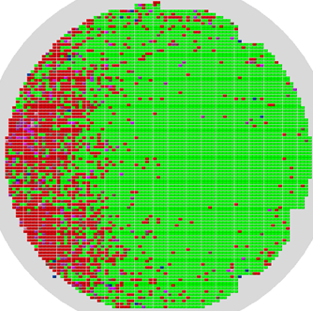

- Data Mining Techniques. Participants learn the strengths and weaknesses of data mining tools used for analysis, including electrical testing techniques, defect inspection tools, wafer map data, and correlation techniques.

- The Process of Yield Analysis. Participants learn to recognize correct philosophical principles that lead to a successful analysis. This includes concepts like destructive vs. non-destructive techniques, fast techniques vs. brute force techniques, and correct verification.

- The course will identify the advantages and disadvantages of a wide variety of tools and techniques that are used for yield analysis.

- The course shows a wide variety of yield visualization techniques that can be used to understand and characterize yield problems.

- Participants will be able to identify basic yield models and equations and their applicability to a variety of semiconductor devices.

- Participants will be able to identify a variety of different failure mechanisms and how they manifest themselves.

- Participants will be able to identify appropriate tools to purchase when starting or expanding a laboratory.