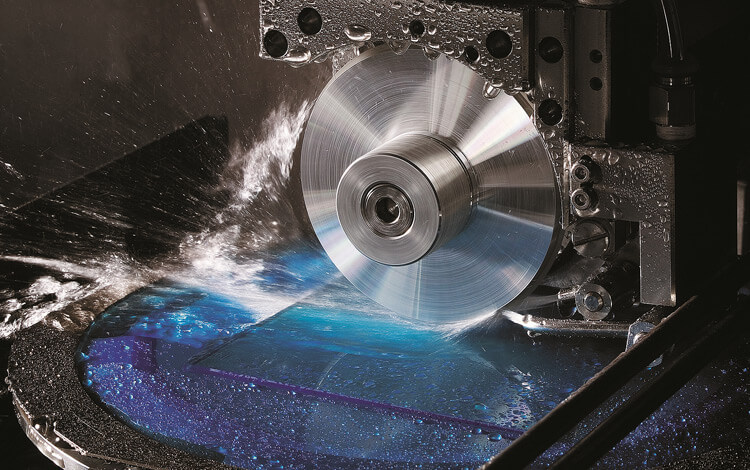

Wafer Dicing is an important part of the semiconductor manufacturing process. After the wafer finishes processing, we need to separate or singulate the die from each other. Engineers can use several different methods to singulate the dice from the wafer: traditional saw blade methods, laser dicing, plasma dicing, waterjet dicing, and other variations. We will discuss these techniques in more detail in this course, along with challenges associated with non-silicon semiconductor wafers, such as GaAs. Wafer Dicing is an 8-hour course that discusses the dicing process in detail. This course is a must for packaging engineers, reliability engineers, product engineers and other personnel supply tools or materials to this segment of the industry.

- The course will provide participants with a fundamental understanding of the dicing process.

- The course will discuss the major processes, as well as newer processes, and their advantages and disadvantages.

- The course discusses the dicing process for non-silicon materials, like GaAs.

- Participants will understand the potential problems with dicing, and how to address them.