Quality is a fundamental aspect of the microelectronics industry. Today’s ICs require ever greater levels of quality and reliability, as the electronics industry incorporates semiconductor components into more applications where the consequence of failure is high, like automotive, industrial, telecom, and medical. Engineers that work in the industry need a strong foundation to understand how to build quality into products. This requires an understanding of how quality impacts subjects like: chip technology, processing, design, testing, qualification and customer expectations. A big part of this is using statistics to ensure the process will yield the desired results. Your company needs competent engineers and scientists who understand these issues. Quality Statistics is a 4-hour long course that offers detailed instruction on statistics that pertain to semiconductor quality. This course is designed for every manager, engineer, and technician working in the semiconductor field, qualifying semiconductor components, or supplying tools to the industry.

Participants learn to develop the skills to determine the best process for qualification, how to identify issues and how to resolve them.

- Overview of Quality and Statistics. Participants learn the fundamentals of quality and how the industry uses statistics, sample sizes, distributions to help quantify quality metrics.

- Statistical Samples. Participants learn what constitutes a valid statistical measure, and how engineers determine the appropriate sample sizes.

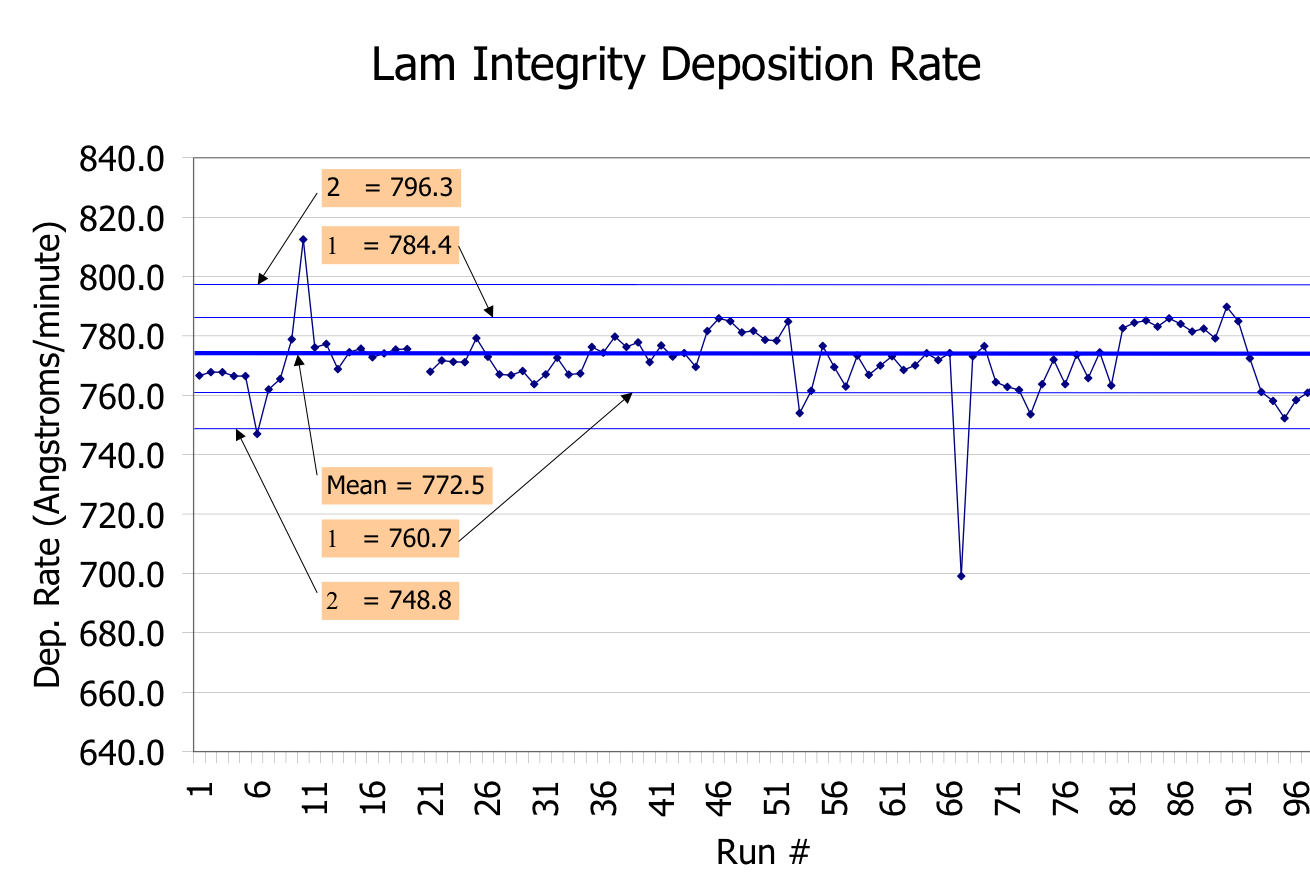

- Statistical Process Control. Participants learn about control charts, how to set one up, and how to monitor the chart.

- Process Capability. Participants learn how to use the Process Capability Index (Cpk) to evaluate the output of a process relative to the limits.

- The course will provide participants with a fundamental understanding of quality statistics and how they are used in the semiconductor industry.

- Participants will understand how we use data and statistics to quantify the level of quality in a product.

- The course will discuss the control chart; explain how they are set up, and how they are monitored during production.

- Participants will understand how determine a valid statistical sample size.